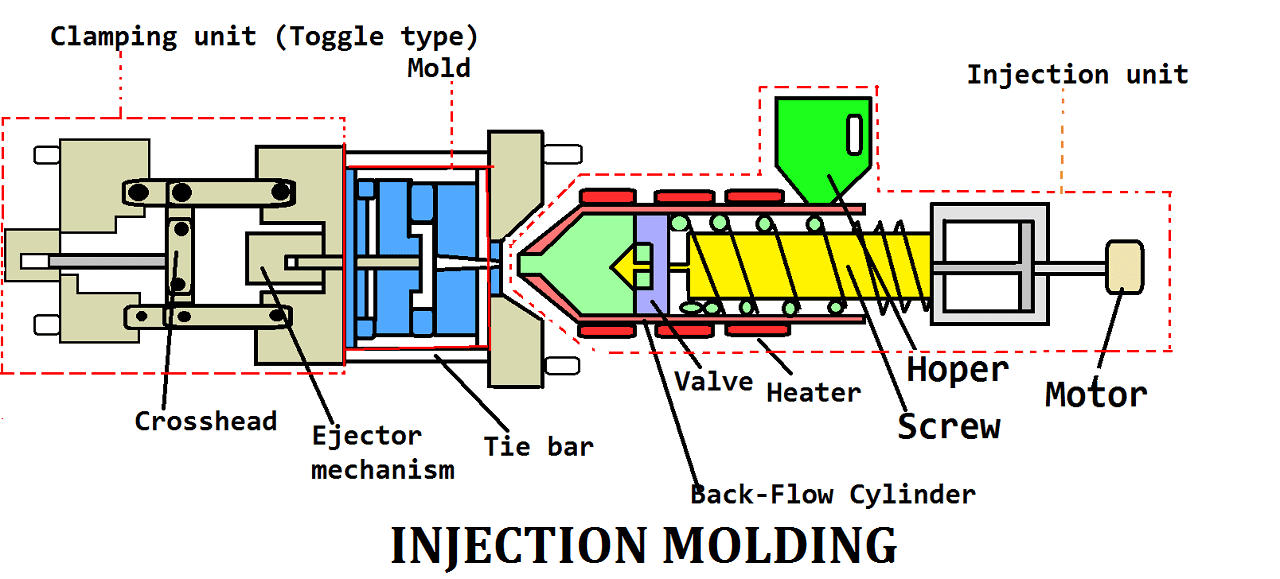

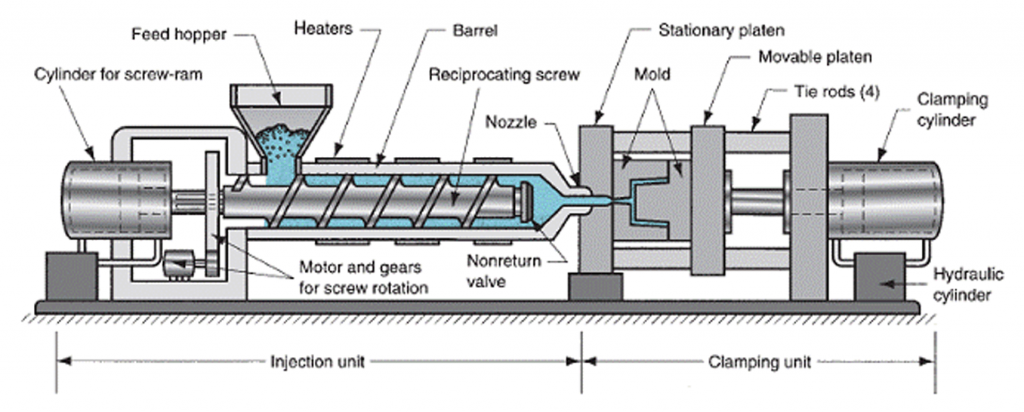

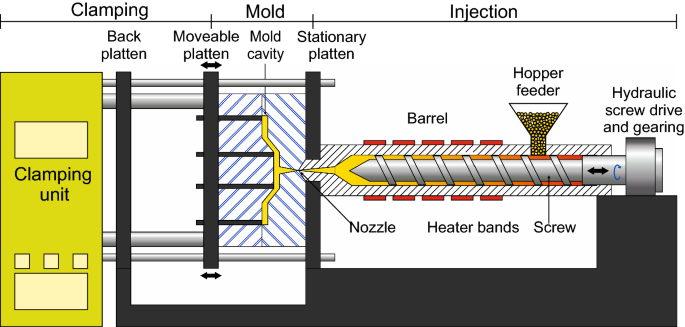

3 Major Functional Units. Injection Mold Clamping 2.

Injection Molding Definition Construction Working Process Advantages Application Notes Pdf

Same items can be moulded in different materials without changing the machine or mould in some cases.

. Inserting a small amount of nitrogen or chemical blow agent into the plastic material makes the walls thicker. MOULDING note ppt for study purpose. Design Guideline for Injection Molding Components.

Foaming happens as the melted plastic material enters the mold cavity. It is typically used as a mass production process to manufacture thousands of identical items. Continuous parts of constant cross section injection molding make discrete parts with.

Where is injection molding. Designing injection molds 1. Moulding Follow Download Presentation.

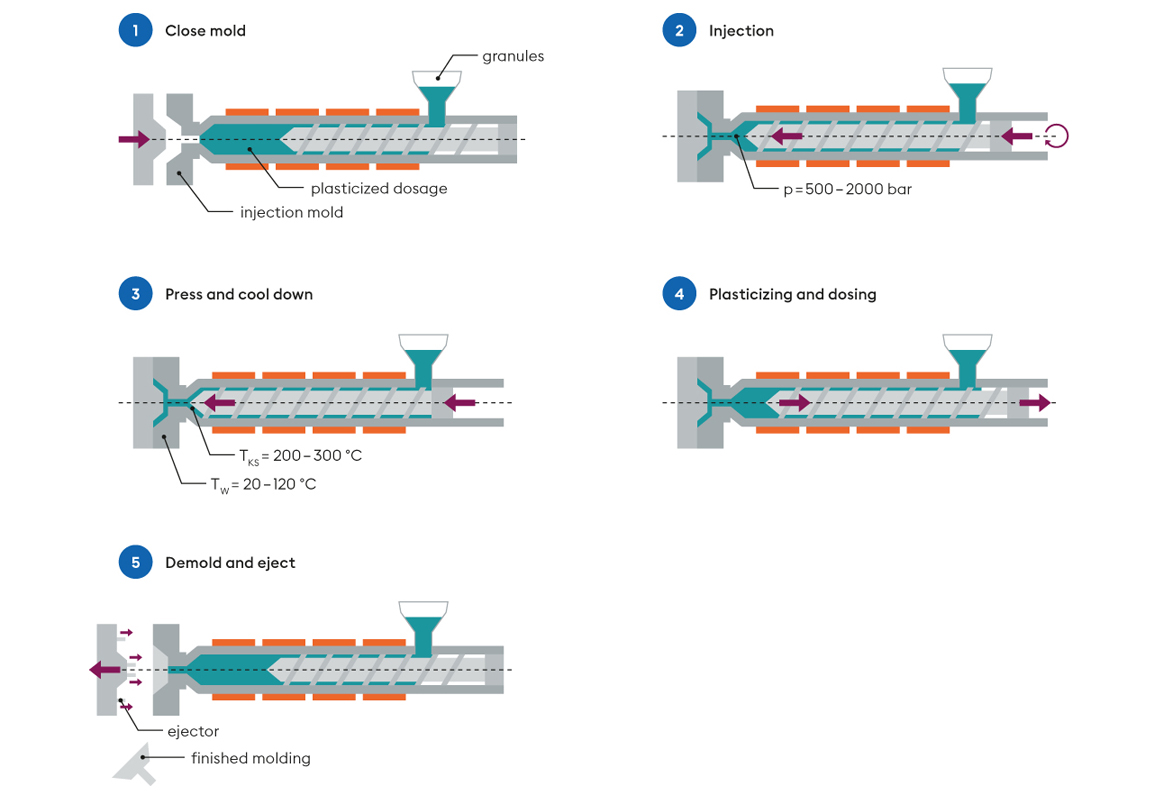

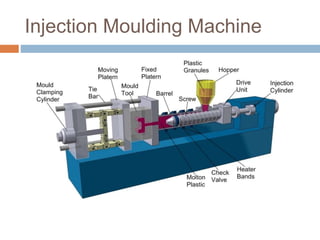

Screw moves forward for injection. Uploaded on Jul 16 2021 CN. Injection moulding machine and components 2.

Screw in full forward position. In contrast to the extrusion which makes. Injection molding is the process that involves injecting molten plastic components into a mould cooling them down and hardening them.

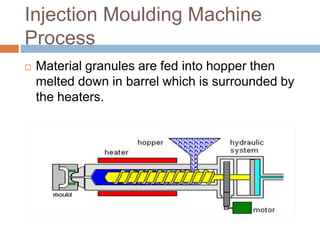

Shrinkage is of order 10-1001000 for unfilled and 1-101000 for filled across the thickness 29 Where is injection molding. Granulated or powdered thermoplastic material is heated melted and then forced under pressure into a mould. Choose the material and the main wall thickness for minimum cost.

Plastic injection mould manufacturer in china - a plastic molding manufacturing company works on injection molding machine and plastic mold meltdown plastics and inject it into the mold by high injection speedonce the plastic is in the mold cavity it forms the shape of the object you desire after the plastics get cold in the mold and eject. A thin plastic skin forms and solidifies in the mold wall. Injection moulding ppt May.

The process is simple in principle. PowerPoint Presentation Injection Moulding Injection point The point where the plastic entered the mould. Once in the mould the material cools forming a component that takes on the shape of the mould cavity.

Hence polymer fillers mold geometry and processing conditions can all influence the final tolerance. Controlled by shrinkage and warping. Gating design where to locate the gates.

Look back at our history there has been massive changes in plastic molding and the use of plastic resins to make useful things. Parting planes by extending the parting line outwards 4. A plastic material usually called a resin is melted and forced into a mould via injection.

A TYPICAL INJECTION MOULDING SYSTEM Basic Phases in Injection Moulding Mould Closes 1st Stage Filling 2nd Stage Packing Cooling and Plasticising Mold Opens Part Ejected. Injection moulding process 3. Parts can be moulded with metallic and non-metallic inserts.

Injection Mouldingppt - Free ebook download as Powerpoint Presentation ppt PDF File pdf Text File txt or view presentation slides online. PowerPoint Presentation Plastic Injection Molding Nachiket Kulkarni 12082016 Introduction Various optical technologies have plastic components Injection molding can achieve mass production Producing components with machining process may be expensive Economical Plastic is an alternative to glass Limited by physical properties. These awesome injection moulding ppt are equipped with all the latest features and are powerful enough to double your business outputs.

To liquify the plastic materials and then inject the liquid into mold Resin is. Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. Is a manufacturing technique for making parts.

PowerPoint PPT presentation. Molding directions number of insertscams required if any 2. Ejection points Plastic must be ejected square to the mould Tapered sides Tapered sides allows the product to be removed from the mould.

Design the main wall of uniform thickness with adequate tapers or draft for easy release from the mold. This will minimize part distortion by facilitating even cooling throughout the part. Injection moulding is the primary method for creating plastic parts components and products.

Detail on Side External Thread TYPES OF UNDERCUT EXTERNAL UNDERCUT It can be removed by Side core actuated by mechanical pins Hydrolic Phumatic cylinders. From thermoplastic and thermoset materials. It works by injecting molten materials into a mould or mold in the United States.

It is a manufacturing technique for making parts from thermoplastic and thermoset materials In contrast to the. Introduction injection moulding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials after a product is designed usually by an industrial designer or an engineer moulds are made by a mouldmaker or toolmaker from metal usually either steel or aluminium and precision-machined to form. The impeccable injection moulding ppt that are found on the site are made of sturdy materials such as robust metals and alloys that offer consistent performances with enhanced durability.

Screw continues moving forward for packing. Injection moulding is a highly automated production process for producing large quantities of identical items. 04 2017 155 likes 49727 views Download Now Download to read offline Engineering Injection moulding process explained with key elements.

These changes have occurred not only with respect to the usefulness of these products in the market as well as the production process of these products in the industry. The technology is well-suited to mass-production of goods with complex forms and it plays a significant role in the field of plastic processing. The following below are explained 1.

Complex and variable cross section. Plastics are by far the most common materials that are produced using injection moulding. Blow Molding Modified extrusion and injection-molding process Characteristics Hollow thin-walled parts of various sizes High production.

Plastic injection moulding ppt 1. Advantages of Injection Moulding Process Minimal scrap loss result as runners gates and rejects can be reground and reused. General accepted design guidelines.

Close dimensional tolerances can be maintained.

The Outline Of Injection Molding

The Plastic Injection Moulding Process Youtube

Basic Knowledge Of Injection Molding Process

Why Choose Injection Moulding Geomiq

What Is The Injection Moulding Ppt Download

Injection Moulding Animation Youtube

An Overview Of The Metal Injection Moulding Process

3 Basic Steps Of The Injection Molding Process Injection Moulding World Magazine

Injection Molding Process Xcentric Mold Engineering

Plastic Injection Molding Process Eas Change Systems Eas Change Systems

Plastics Processes Injection Moulding

Injection Molding Manufacturing Process Review Of Case Based Reasoning Applications Springerlink

Processing Cycle Of Conventional Injection Molding Process Source Download Scientific Diagram